Four Keys to a Successful Automation Implementation

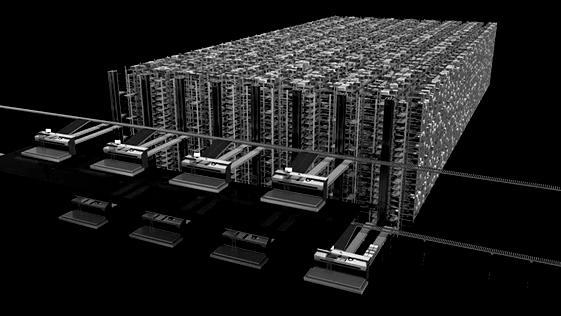

Automated warehouse equipment has been around for decades, improved vastly over time, and has become commonplace in a growing number of distribution and manufacturing environments. More and more companies today are looking to expand their automation capabilities as well as number of processes withing their operations. Millions of dollars are spent on consulting studies, network studies, and engineering studies to determine the viability and costs of automated equipment, but a key element to successful automation adoption is often overlooked: a solid plan for implementation.

Here are four key elements of a successful automation implementation:

1. Hiring/training a robust automation team

In my mind this is the biggest missing piece for most organizations. Having internal industrial engineers, WMS/ERP software experts, and operations personnel is a good thing and will help the overall business, but these teams are often working on several projects or putting out fires in their respective departments and responsibilities. Having a dedicated (internal) team working on each project ensures that key elements of your business and business rules are not missed throughout the process, and can better hold the technology provider accountable for those items during the testing and implementation phase of a project. These employees need to be hired EARLY in the process so that they know your business, or if you are pulling them from internal resources their replacements need to be up and running so these employees can be fully dedicated. This element needs to be factored into any ROI calculation in “Year 0”, but the long term savings are immeasurable to have these team members on staff. Here are some examples of team members to hire before the automation journey begins:

- Director of Automation Engineering

- Director of Operations, Automation

- Systems Integration Engineer

- Dedicated IT specialist for selected Warehouse Control System

- HR/Training manager, Automation

It should also be noted that not all warehouse team members can/will be willing to be cross trained for the automation equipment. Let’s face it: standing in front of a GTP for an entire shift is not the most fun job in the world. Plan to move team members around to different functions throughout the week, and pay attention to point #4 below, with realistic KPI’s.

2. Overcommunicate & Document

This should go without saying, but the need to overcommunicate and document every meeting with minutes can not be understated. Controlled documents, such as a software functional specification, can be incredibly long and cumbersome – but still miss key elements to your specific business processes that were discussed in previous meetings. Have a dedicated team member record the meeting minutes of EVERY meeting and call. This way there is a record for others to review and make necessary changes if something was missed. Everyone is busy these days, including your technology partner. Although they have a consistent team working on your project from several disciplines the truth is that those same team members may be working on a number of different projects. Although it may not be with malicious intent, when people are over busy things can be missed. It should seem obvious, but getting as much right and documented prior to testing and go-live is a major key to success. There will ALWAYS be a couple of frustrating issues during go-live. But making these mole-hills versus mountains starts with excellent communication and over-documentation.

3. Eliminate “would”, “could”, and “should” from your vocabulary

“My system should (insert seemingly simple functionality here)”. Eliminate this sentence, along with any including “would” and “could” from your repertoire. Never assume that your technology partner knows more about your business and your business processes than you do. Create a process flow and SOP’s BEFORE automating, so that you can map these processes with automation included. Controlled documents, while not always set in stone – are what your technology partner is going to build your system to do. Many times, the teams coding and programming your system have never set foot in your operation, and are building your software to the EXACT specifications written into the controlled documents. Something that may seem like a “common sense” business operation is a complete unknown unless it is written into your controlled specification documents. This is a hard truth, but automation ONLY DOES WHAT YOU TELL IT TO DO. There are certain technologies that will “learn” over time and improve their own processes, but functionally knowing that a packing slip only goes into boxes for customer A and not customer B is something that must be programmed up front. A robotic arm column stacking boxes will not decide to interleave the boxes unless you tell it to up front. This is all bleeds back into point numbers 1 and 2; having a dedicated team that can make sure none of these items are missed, and documenting everything.

4. Set realistic and achievable KPI’s for the 1st and 2nd year

Automation is amazing and is improving as I type this blog. However, the minute you turn the machine on, it is very unlikely that it will run at the rates contracted by your technology partner. There are a few reasons for this:

There could be some kinks in communication between the host and automation systems at full volume; no matter how much testing you perform, nothing compares to full production

The system takes time to load; for systems like shuttles and pallet ASRS, it can take weeks if not months to load all of you product into the system. As much as your technology partner may tell you that they could (read: don’t want to) load some of your product into the system during testing, the truth is that it is testing. This means that they are testing all elements of the system, including their ability to track inventory. Do you really want them to start storing high value items if they aren’t sure yet if they will know where it is once it’s stored?

Your team members need time to get used to the system. Were you great at driving a car the first time you got behind the wheel? You might have been because you are smart enough to be reading this blog post. However most people need time to get experience and be good at anything new. Give your team members time once the system is loaded to get up to speed

For the above reasons and a myriad of others, plan to set realistic expectations for the first and second years your system is in use. This is also an important element to consider in your ROI calculations. Once the system has been running for no less than 6-months, re-evaluate your achievable goals and then begin to raise the KPI expections so that you don’t burn out your team members. Everyone likes hitting goals. Everyone likes bonuses. Make these achievable based on reality, not a pie-in-the-sky number you came up with before you turned the machine on.

5. BONUS ELEMENT: Have fun!

Technology is awesome, and supply chain is one of the most interesting industries to be in. There is something new and something to learn every single day, no matter how long you’ve been in the business. So have fun. Take your teams out to celebrate the small victories. Have a party for hitting your goals. Cheers!