Caja Robotics Logistics Workshop - Bochum, Germany, Nov. 12

Warehouse Space & Workforce Efficiency Workshop

Overview:

On November 12th Caja Robotics, together with Versand Manufaktur GmbH, organized a supply chain conference in Bochum, Germany, co-hosted by Hoermann Logistics, Agilox, Packsize, and Logivest. In addition, Versand Manufaktur GmbH organized a tour of their warehouse and fulfillment center in Bochum, where they showcased various automated system technologies. This report intends to summarize the learnings and take-aways form that event.

Summary:

Caja Robotics

Caja Robotics is a warehouse automation technology company specializing in robotic solutions for small parts storage and order fulfillment. Their innovative and scalable system uses standard shelving and cardboard boxes for storage, paired with a fleet of robots operating on a goods-to-person workflow.

With a philosophy of “more software, fewer robots,” Caja Robotics prioritizes maximizing efficiency through advanced software and AI. This approach minimizes the number of robots needed while ensuring fast and accurate order fulfillment, making their solution both cost-effective and highly efficient.

At the core of their system is a sophisticated warehouse execution software (WES) platform, a black-box solution that handles all warehouse operations, from receiving to storage and fulfillment. The software optimizes robot tasks and processes, allowing for a smaller robotic fleet compared to other automated case-handling robot (ACR) systems.

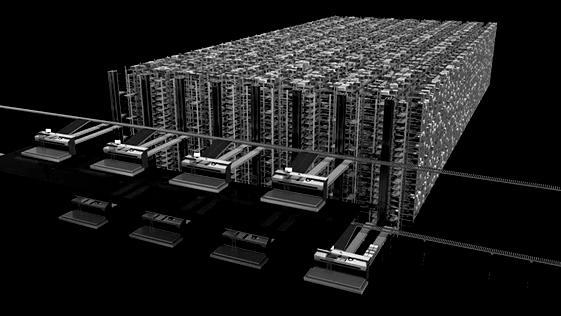

Caja’s hardware components are designed to be cost-effective, utilizing standard industry materials like static shelving and cardboard boxes instead of expensive custom racks or totes. This simplicity significantly lowers hardware costs while maintaining high functionality.

The system employs two types of robots working together: taller “storage” robots retrieve cartons from shelves and transfer them to smaller “runner” robots, which deliver items to goods-to-person picking stations. This setup enables productivity rates of up to 350 order lines per hour and over 500 picks per hour per station. The robots have a vertical reach of 5.2 meters and can handle cartons weighing up to 30 kilograms.

Scalability is another key advantage of the Caja Robotics system. Additional robots can be integrated to boost performance, and storage capacity can be expanded by adding more shelving units. The straightforward design and use of standard components highlight the solution’s thoughtful engineering.

With an uptime exceeding 99%, the system is reliable and performs exceptionally well. Caja Robotics can implement a system with 14,000 storage locations and 60 robots in just eight weeks, offering a quick and minimally disruptive setup. This rapid deployment makes their solution particularly attractive for existing facilities, enabling fast operational benefits compared to traditional alternatives.

Key Takeaways from the workshop

- Automation is a great solution to adapt to the dynamic and changing environment of logistics, according to Caja Robotics

- The Caja Robotics solution is based on the principle of more software – less robots. For example, this is reflected in their Ai driven inbound and put-away process. This process focusses on optimizing the lowest cost per storage location based on a smart algorithm and predictive order fulfillment capabilities

- The software can also fulfill orders directly from new inbound product vs picking from existing stock, thereby removing the need for time consuming storage and retrieval movements

- Their intelligent fleet management software adds a 4th dimension to calculate the fastest, not always the shortest route for storage & retrieval and order fulfillment

- For storage mediums, the Caja Robotics solution doesn’t rely on plastic totes alone but can also store carboard and carton. This reduces storage cost

- The storage rack or shelving used has a very simple and fast set-up and costs significantly less than the racking of comparable ASRS goods-to-person solutions

- Upfront investment can be kept low as the number of robots is scalable over time and the storage rack can easily be expanded in future without disrupting the existing operation

Conclusion

Caja Robotics delivers a powerful yet cost-effective solution for companies seeking to modernize their warehouse operations. Their innovative approach leverages advanced software to minimize hardware requirements, setting a new standard in automation efficiency.

The system's scalability makes it ideal for both entry-level automation and high-performance operations, adapting seamlessly to the evolving needs of businesses. With independently operating robots, the solution ensures full redundancy and boasts impressive uptime reliability, making it a dependable choice for optimizing warehouse performance.

For more information visit www.cajarobotics.com

Author: Christoph Buchmann, November 19th 2024

Disclaimer: The views expressed in this white paper are solely the opinion of the writer and are not associated with any corporate entity. This is a personal blog. Any views or opinions presented are personal and belong solely to the author and do not represent those of people, institutions, or organizations that the owner may or may not be associated with in a professional or personal capacity, unless explicitly stated. Any views or opinions are not intended to malign any organization, company, or individual.