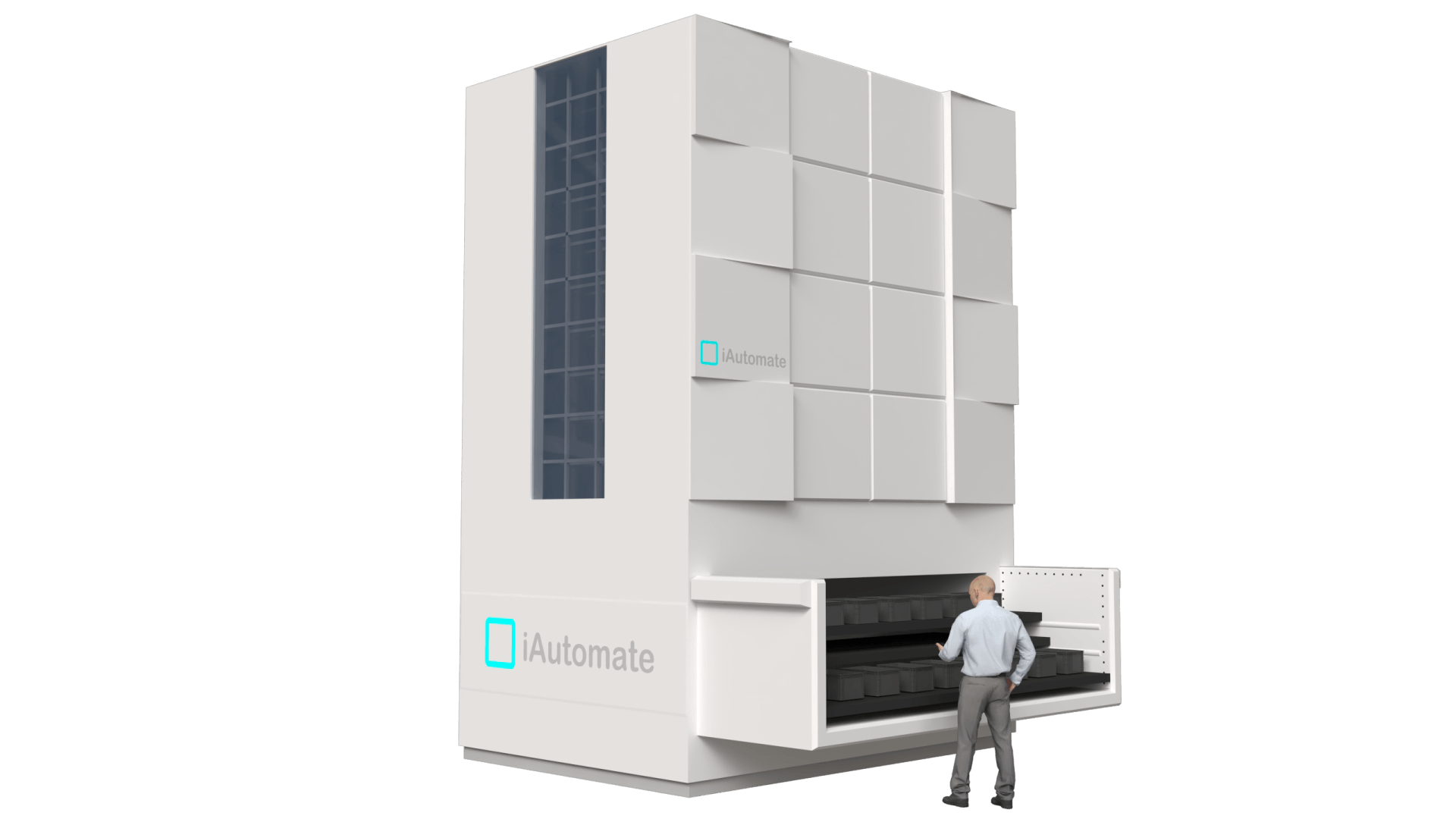

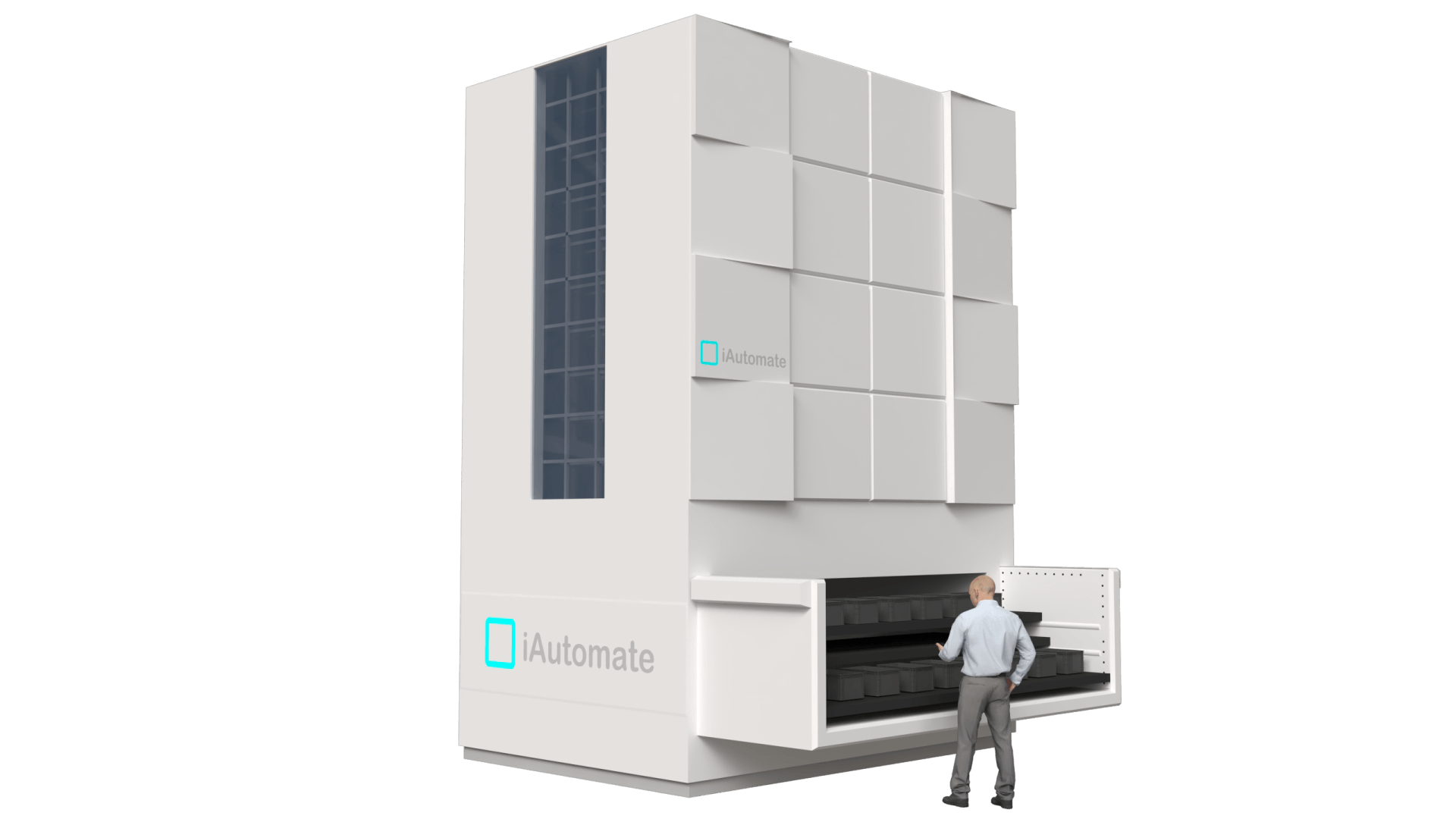

Vertical Lift Module:

A Vertical Lift Module (VLM) is a high-density vertical automated storage and retrieval system designed for small parts and single unit picking. These types of automated system solutions apply to several different industries including manufacturing, distribution, retail and warehouse operations. A VLM consists of storage trays in the front and back and an inserter/extractor system that runs down the center. Trays are automatically retrieved and delivered to a pick window for order fulfillment.

VLM’s are designed for slow moving articles and are an ideal solution for maximizing vertical cube up to 80% while providing access to hundreds of SKUs. These solutions are scalable in height and can increase picking productivity and accuracy.

Product Overview:

- Automated storage and retrieval system

- Small parts storage and handling

- Goods-to-person order fulfillment

- Integrated controls system

- High storage density solution

Solution Benefits:

- Automated storage solution

- Increase productivity and accuracy

- Saves up to 85% floor space by utilizing full ceiling height

- Dynamic shelving maximizes storage density

- Scalable and customizable solution

- Improved ergonomics for picking

- Easy software integration

| UOM | Value |

|---|---|

| Load Handling Unit | Single units, cases or trays |

| Load Capacity per Tray | 1,000Kg / 2,200 Lbs |

| System Length | Variable |

| System Height | Max. 30m / 98’ |

| Avg. Picking Performance | 60 – 100 units/h per FTE |

Solution Limitations:

- Slow access to storage trays and product. Presenting the required tray is time consuming and results into idle picking time

- Designed for slow moving SKUs. Unsuitable for medium to fast moving SKUs

- Picking productivity limited to an average of 100 units/h per FTE

- Only 1 FTE can be working on a single VLM

- The higher the system the lower the picking productivity due to tray exchange times

Technology Providers:

- Kardex

- SSI Schaefer

- Modula