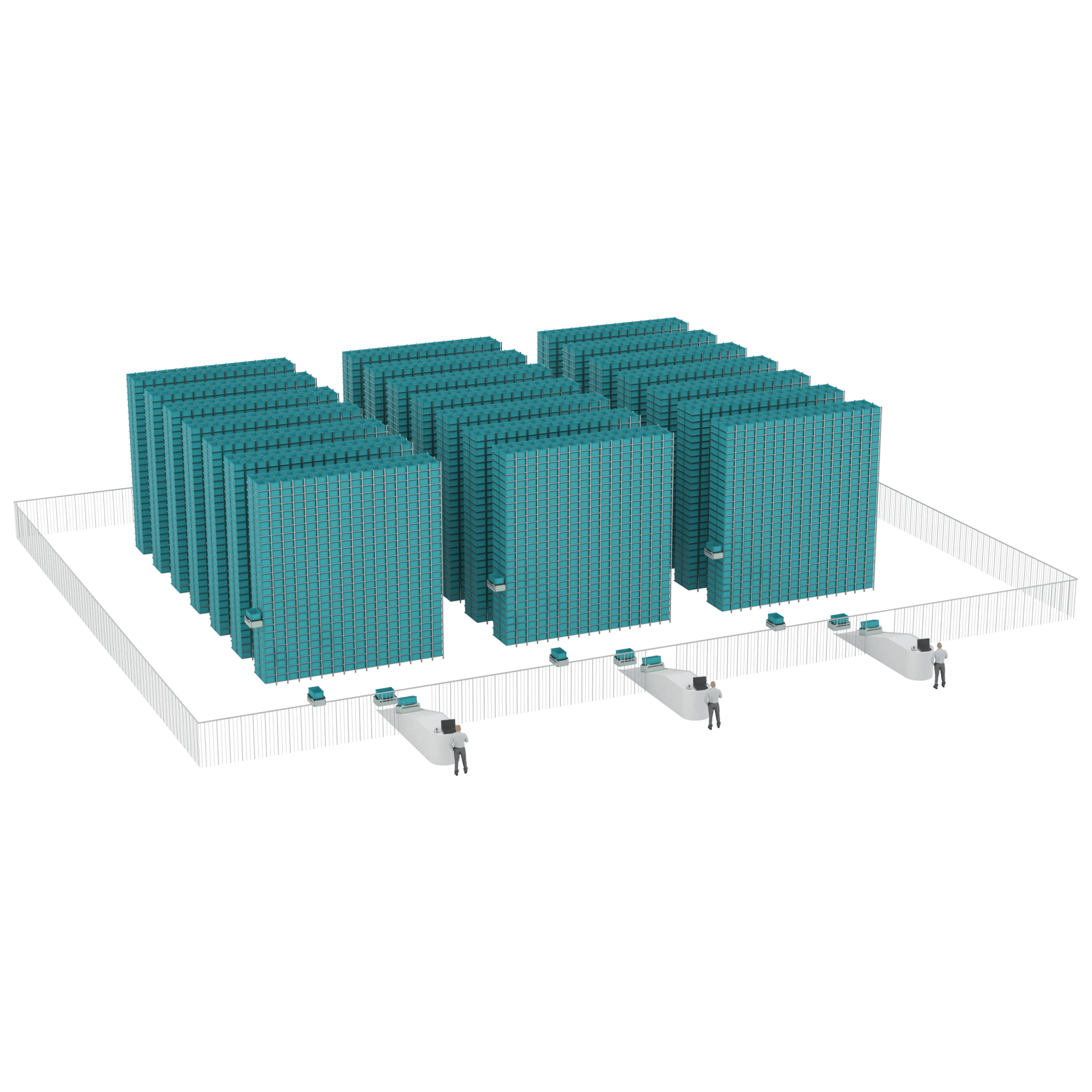

3D Robotic Storage System:

3D robotic storage systems are automated storage and fulfillment systems, providing a high level of scalability and modularity combined with operational redundancy. These systems are commonly viewed as the evolution of captive aisle shuttle systems. Robots move autonomously in three dimensions via horizontal movement on the floor and vertical movement anywhere in the rack providing instant access to all totes/SKUs. This allows for fast response times and scalable expansion, as more robots can be added over time, or by expanding the existing storage grid. These solutions do not provide the highest storage density per square foot compared to other solutions but offer fast and efficient order fulfillment through their innovative design based on autonomous 3D moving robots. Order fulfillment is based on Goods-to-Person picking technology. These system solutions are the evolution of cubic storage systems boasting absolute scalability in performance and instant access to product through the 3-dimensional robot movement.

Product Overview:

- Automated storage and retrieval system

- Small parts storage and handling

- Tote storage medium (multiple heights)

- Goods-to-person order fulfillment

- Intelligent software management system

- Autonomous roaming robots

Solution Benefits:

- Automated storage and fulfillment

- Fast access to all products and totes

- High order fulfillment performance

- Provides operational redundancy

- Scalable and modular performance and design

- Lower and scalable upfront investment

- Robots move in 3 dimensions

| UOM | Value |

|---|---|

| Load Capacity | 15KG / 55 Lbs |

| System Length | Variable |

| System Height | Max. 11m / 36' |

| Performance per roboter | 15 - 20 DC/h |

Solution Limitations:

- Sub-optimal storage density due to rack design. Single deep storage, many access aisles required leading to loss of valuable storage space

- Requires large front-zone to prevent robot congestion impacting performance

- # of operating robots limited by grid size which limits achievable system performance

- Sub-optimal robot recovery strategy causing substantial operational downtime

- System grid height limitation of 36’

- Many moving mechanical elements in robot. Subject to heavy wear and tear over time

- Expensive service and maintenance contracts

- Solution has comparable high level of complexity

Technology Providers:

- Attabotics

- Exotec

- Opex - Infinity