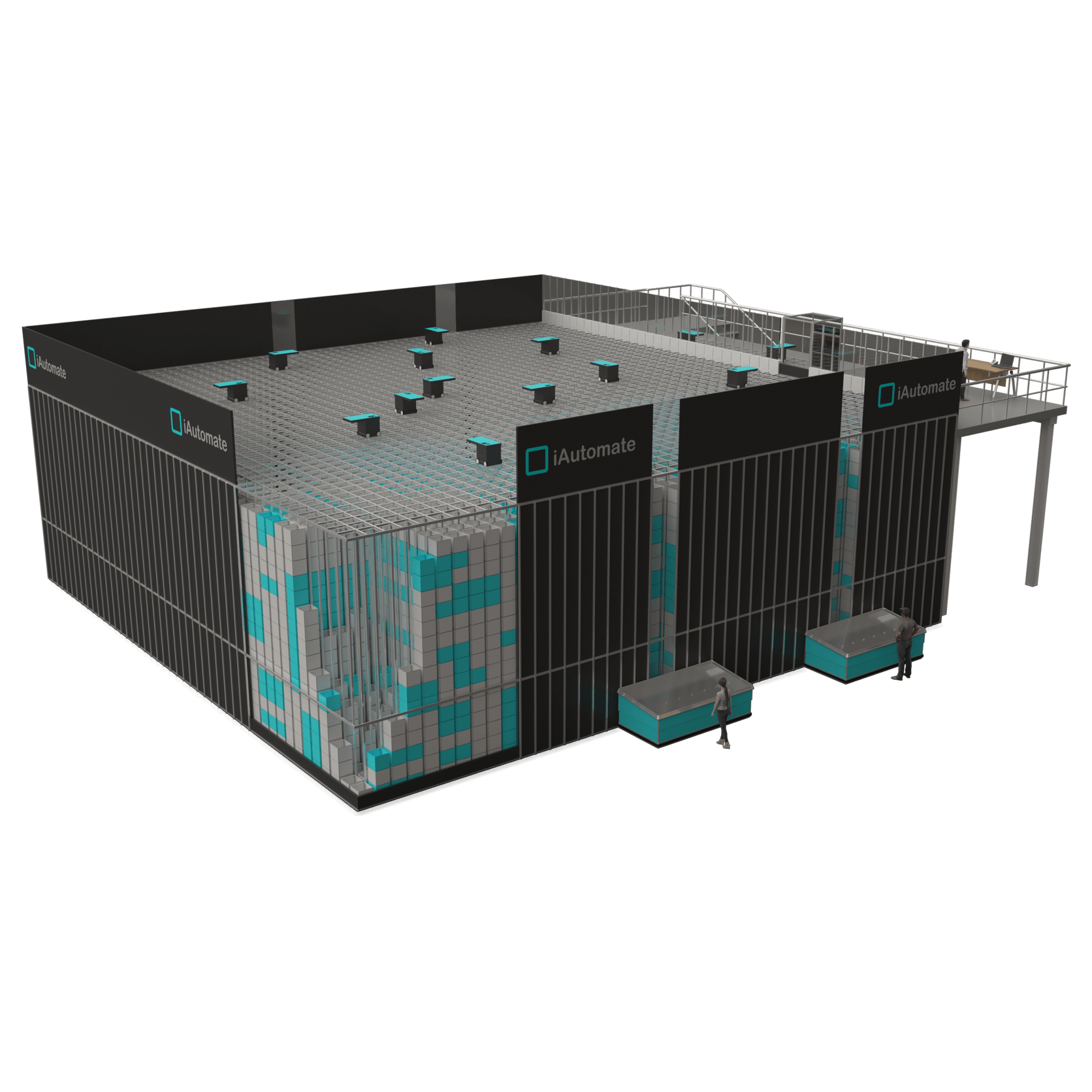

Cubic Storage System:

Cubic storage systems are automated storage and fulfillment systems combining highest storage density with flexible and redundant performance. Robots roam in two dimensions on top of the storage grid connecting storage and picking based on the goods-to-person order fulfillment principle. These solutions provide highest storage density per square foot by stacking storage totes on top of each other enabling deployment in low ceiling height buildings. Robots can access storage totes by digging totes out. This is time consuming, impacting performance and is the major disadvantage of this type of solution. However, its storage density is unrivalled compared to other warehouse automation solutions. Space optimization and scalable throughput improve order fulfillment productivity and reduce cost per picked unit and storage cost per square foot. These systems are easily expandable and support future growth. Cubic storage systems offer the best-in-class storage density but are not considered high performance systems, as performance is impacted by the need to dig for storage totes.

Product Overview:

- Automated storage and retrieval system

- Small parts storage and handling

- Tote storage medium (multiple heights)

- Goods-to-person order fulfillment

- Intelligent software management system

- Roaming robots

- High storage density system solution

Solution Benefits:

- Automated storage and fulfillment

- Highest density storage system

- Provides Goods-to-Person order fulfillment

- Improves inventory management accuracy

- Scalable and modular performance and design

- Designed on operational redundancy

| UOM | Value |

|---|---|

| Load Capacity | 30KG / 66 Lbs |

| System Length | Variable |

| System Height | Max. 5.4m / 18' |

| Performance per roboter | 15 - 25 DC/h |

Solution Limitations:

- Limited access to storage totes and product. Tote digging always required since only top storage level instantly accessible by robots

- Requires frequent robot charging times resulting into loss in productivity

- Performance heavily dependant on 80/20 ABC SKU pareto curve

- Sub-optimal robot recovery strategy causing substantial operational downtime

- System grid height limitation of 18’ (+6’ for service access) = 24’ max height

- System throughput very vulnerable to changes in order profile and SKU velocity

- Robots require a 30 min. order preparation time prior to order fulfillment

- Annual robot fees and not tote agnostic. Requires special tote design

Technology Providers:

- AutoStore

- Ocado

- Intellistore

- Jungheinrich - Powercube