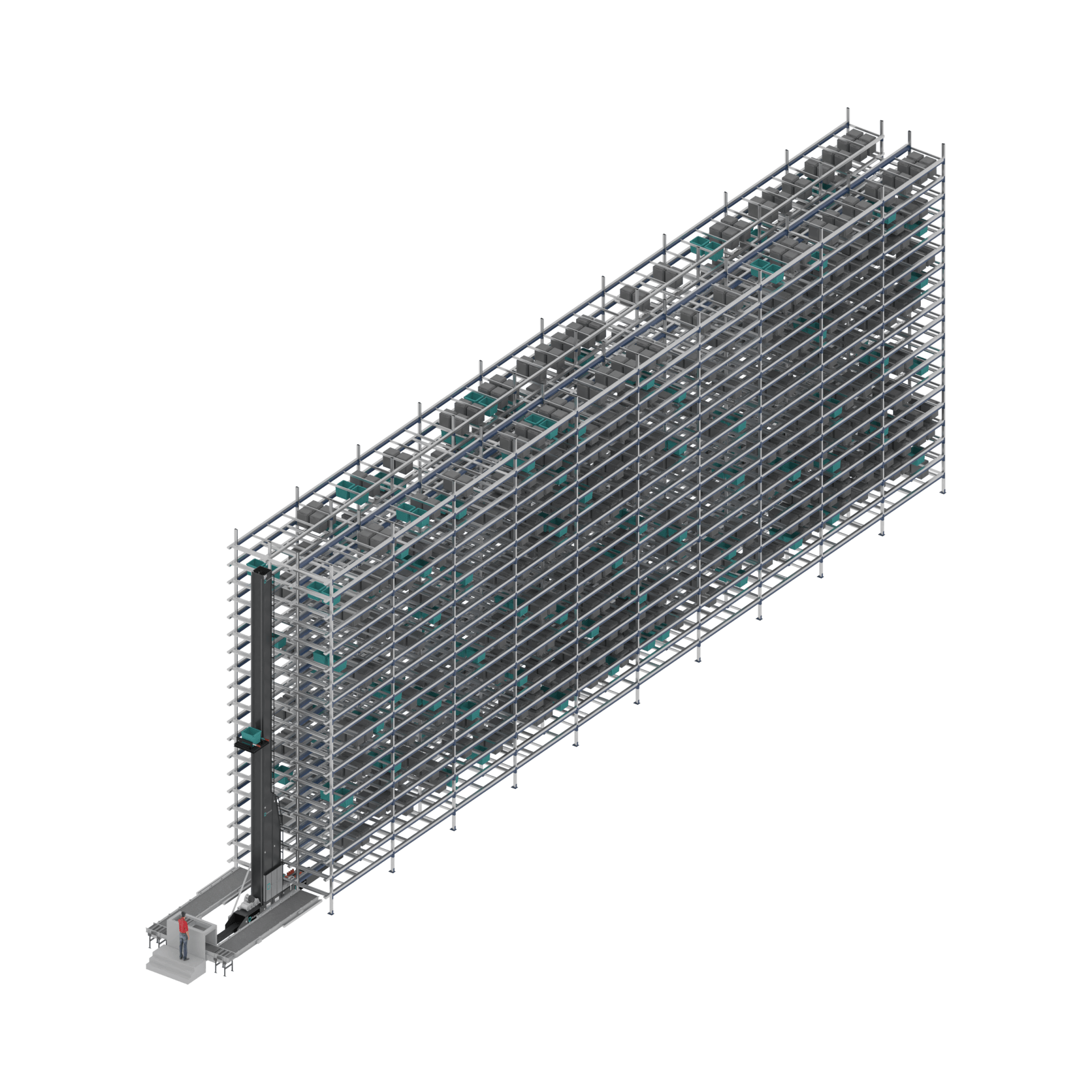

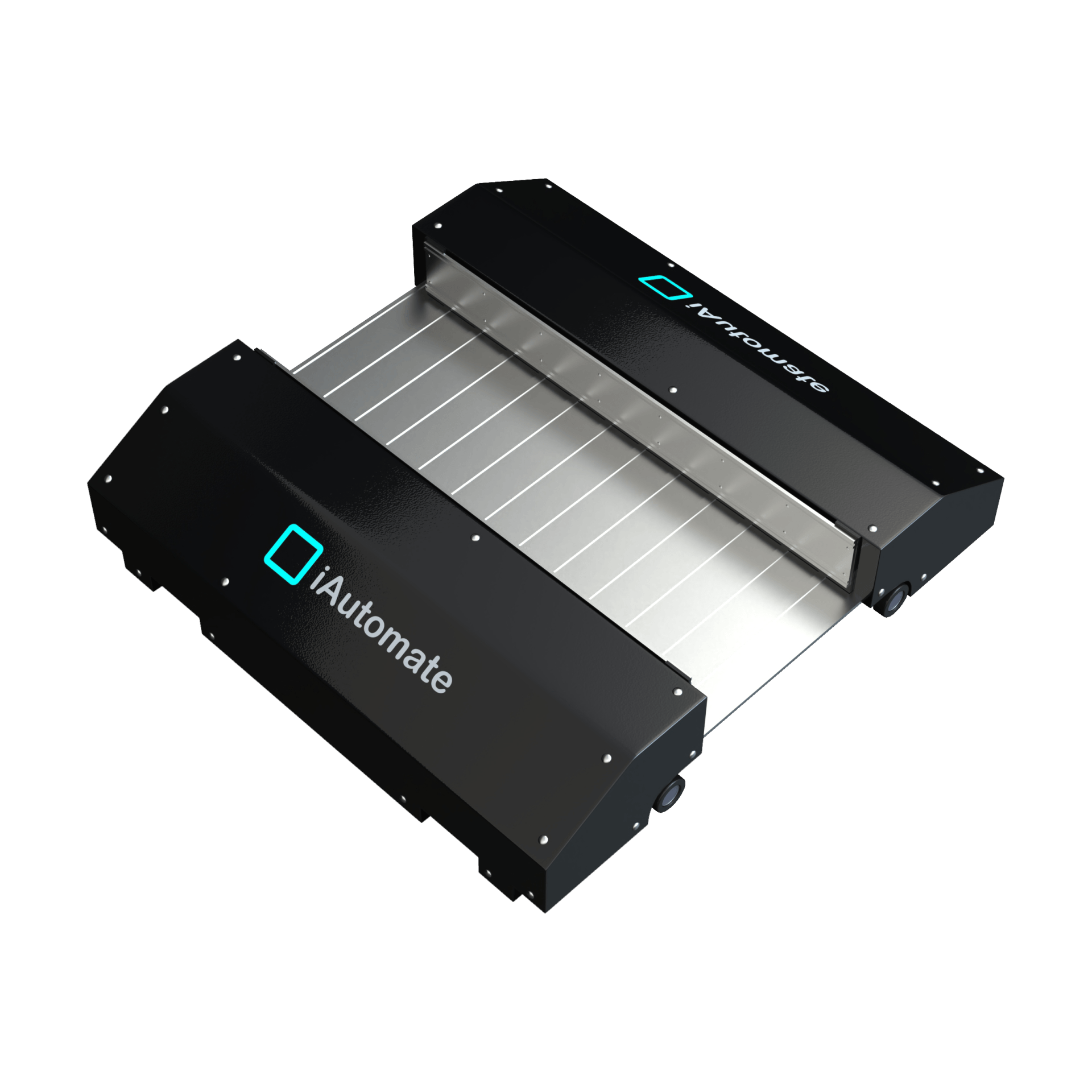

Captive Shuttle:

Captive shuttle systems are automated storage and retrieval systems that enable order fulfillment based on the goods-to-person concept. These systems optimize the utilization of warehouse storage space and significantly improve order fulfillment productivity and inventory management accuracy. The storage rack is designed to hold one shuttle per level and can store product single, double or multiple-deep. Shuttles retrieve product (totes, trays, cartons) from the rack and hand over the product to a lift which feeds a conveyor front-loop. Captive shuttle systems are designed to handle various load handling sizes and are configurable, modular and scalable system solutions. These systems have been on the market for many years and are highly reliable and robust system solutions. In recent years these systems have evolved into roaming shuttle systems, removing the element of being aisle-captive.

Product Overview:

- Automated storage and retrieval system

- Small parts storage and handling

- Tote, tray, and carton handling

- Single to multi-deep storage rack

- Goods-to-person order fulfillment

- Intelligent software management system

- Aisle-captive shuttle system

- High performance system solution

- Goods-to-Person order fulfillment

Solution Benefits:

- Automated storage and product handling

- Optimized warehouse storage space

- Increases order fulfillment productivity based on Goods-to-Person picking

- Improves inventory management accuracy

- Handles totes, trays and cases

- Scalable and modular system solution

- Highest system performance of small parts ASRS system solutions

- Designed to handle fast, medium and slow moving SKUs

- Sequencing order fulfillment ability

- Ability to integrate an order shipping buffer

| UOM | Value |

|---|---|

| Load Capacity | 35KG / 77 Lbs |

| System Length | 120m / 400' |

| System Height | 20m / 65' |

| Performance per Aisle | 500 - 750 DC/h |

| Performance per Shuttle | 30 - 60 DC/h |

Solution Limitations:

- Single point of failure. If front-end lift is down, the entire aisle is down, and product becomes inaccessible

- Shuttles are typically underutilized since front-end lift becomes performance bottleneck

- Solution only scalable by adding additional aisles

- Requires high upfront investment

- Rigid – Once built aisles are not expandable in height, width, or length

- Requires frequent preventive maintenance

- Solution has comparable high level of complexity

Technology Providers:

- Knapp

- SSI Schaefer

- Dematic

- Swisslog

- Intelligrated

- Vanderlande

- TGW

- Rocket Solutions

- Daifuku