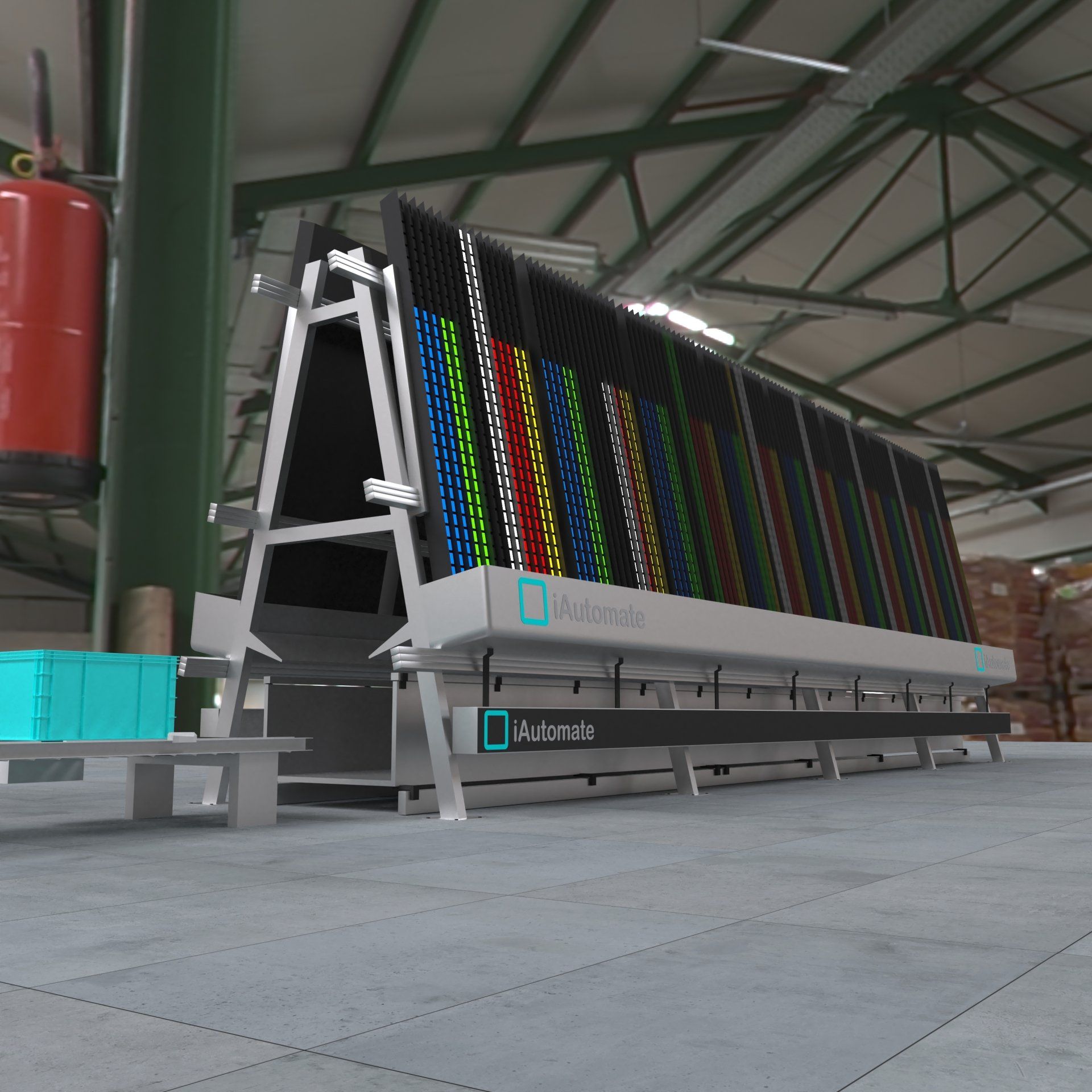

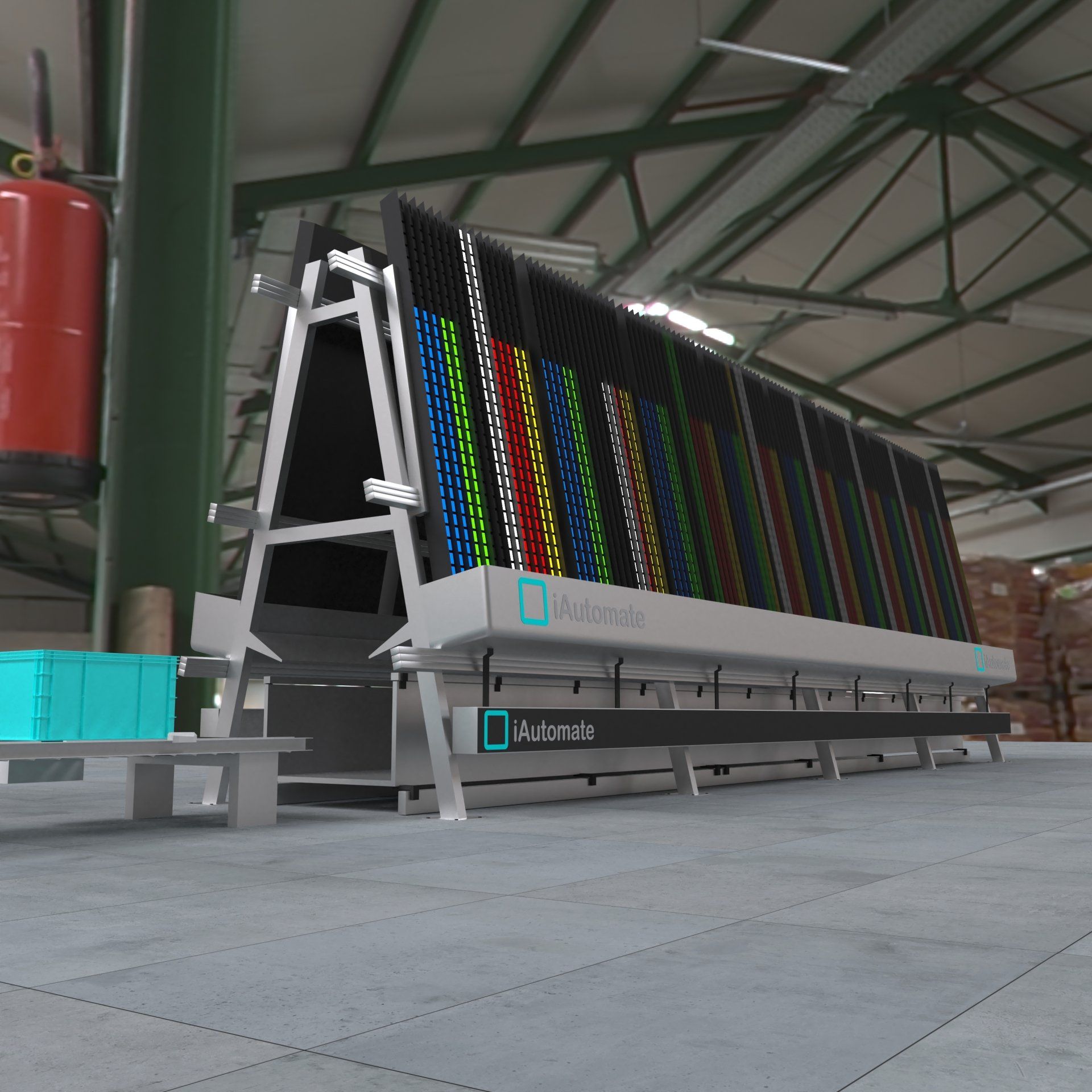

A-Frame:

An A-Frame is a fully-automated picking system used to fill orders with manually pre-loaded single units at a very high speed, accuracy and quality. They are mainly deployed in distribution centers for pharmaceutical products, where the packages are small and standardized and mostly part of an overall solution where they handle fast moving products and help to cover peak fulfilment hours.

Product Overview:

- Fully-automatic picking

- Manual replenishment

- Connect to a conveyor system

- Best suitable for small single units in rectangular packaging

- Often used for high velocity items

Solution Benefits:

- Can be loaded at down-times

- Operate with limited manual intervention at peak times

- Scalability in length

- Some flexibility due to changes of the channel’s length

- Fast movers are replenished in bulks

- Relieves operations picking during peak time

- Proven technology used since many years

- High accuracy rates

| UOM | Value |

|---|---|

| System Length | 10 – 100 m / 33’ – 330’ |

| System Depth | 4 m / 13’ |

| System Height | 3 m / 10’ |

| Load Capacity (per article channel) | 15 kg / 33 lbs. |

| Performance per Line | Up to 1.500 order totes/cartons per hour |

Solution Limitations:

- Packaging sizes, weights and shapes limited

- Scales in length, can require a long building

- Requires a good understanding of expected article velocities (slotting)

- No fit articles will still need to be handled in other areas

- No flexibility in the usage of clear height

Technology Providers:

- Knapp

- SSI Schaefer

- Inther Group

- SI Systems

- Conveyco